A 40ft container can hold approximately 500 to 600 solar panels. Transforming your shipping container into an off-grid living space has become increasingly popular, and adding solar panels is a great way to achieve sustainability.

By utilizing a solar power kit, you can easily connect all your essential appliances, ensuring a smooth transition to off-grid living. Installing solar panels on your shipping container not only provides a renewable energy source but also reduces your carbon footprint and energy costs.

With advancements in technology and large-format solar panels, you can maximize the energy output while utilizing the available space efficiently. Consider stacking solar panels on top of your shipping container to make the most of your renewable energy setup.

Maximizing Space Utilization

When it comes to solar panel installations, space utilization plays a crucial role in optimizing the efficiency of the system. One of the key considerations is determining how many solar panels can fit in a 40ft container. The dimensions of both the solar panels and the container itself, as well as the spacing requirements for installation, are important factors to take into account. By carefully assessing these factors, you can ensure that each container is utilized to its maximum potential, allowing for a greater number of solar panels to be installed.

Considering Dimensions Of Solar Panels And Container

The size and shape of the solar panels have a direct impact on how many can be accommodated within a 40ft container. Solar panels come in various dimensions, typically ranging from standard 60-cell panels to larger 72-cell panels. It is important to consider these dimensions and determine the optimal layout for fitting as many panels as possible within the container.

Additionally, the dimensions of the container itself must be taken into account. A standard 40ft container usually has internal measurements of approximately 39.4ft length, 7.7ft width, and 7.9ft height. By analyzing the dimensions of both the solar panels and the container, you can design an efficient layout that maximizes the use of available space while still considering accessibility for installation purposes.

Assessing Spacing Requirements For Efficient Installation

Spacing between solar panels is another crucial factor in maximizing space utilization. While it is important to fit as many panels as possible, adequate spacing must be maintained to ensure proper installation, maintenance, and optimal performance. The spacing requirements will depend on factors such as panel size, orientation, and tilt angle.

An efficient layout will ensure that the panels are evenly spaced and angled to avoid any shading or interference with neighboring panels. This can be achieved through careful planning and the use of mounting systems that provide flexibility in panel arrangement.

Moreover, it is important to consider the available clearance height within the container. This will determine the maximum number of rows that can be installed vertically. By precisely assessing the spacing requirements, you can determine the optimal number of solar panels that can be installed in a 40ft container, while still adhering to safety and performance standards.

By considering the dimensions of both the solar panels and the container, as well as assessing the spacing requirements for efficient installation, you can effectively maximize space utilization. This allows for a greater number of solar panels to be installed in each container, ultimately increasing the overall energy-generating capacity of the system.

Credit: www.youtube.com

Stackability And Arrangement Techniques

When it comes to shipping solar panels, maximizing container capacity is crucial for cost-efficiency and sustainability. Optimizing the stackability and arrangement techniques of solar panels can significantly increase the number of panels that can be transported in a 40ft container, reducing shipping costs and minimizing environmental impact.

Optimizing Panel Layout To Maximize Container Capacity

One of the key factors in maximizing container capacity is the panel layout. By strategically organizing the solar panels, space can be utilized to its fullest potential. Here are some techniques to consider:

- Orientation: Solar panels can be arranged horizontally or vertically to fit more panels in the container. Assessing the dimensions of the panels and container can help determine the optimal orientation for maximum capacity.

- Racking systems: Utilizing racking systems can help in organizing the panels efficiently. Adjustable or folding racks can be used to stack panels in a way that minimizes wasted space and ensures stability during shipping.

- Interlocking: Interlocking solar panels can be an effective way to utilize space. By positioning panels in an interlocking pattern, it reduces the gap between them, maximizing the number of panels that can be fitted in the container.

- Uniform arrangement: Ensuring a uniform arrangement of solar panels can help optimize container capacity. By aligning and positioning panels in a systematic and consistent manner, wasted space can be minimized.

Exploring Different Stacking Configurations For Increased Efficiency

Besides panel layout optimization, exploring different stacking configurations can further enhance container capacity. Here are some stacking techniques to consider:

- Flat stacking: This technique involves stacking solar panels flat on top of each other, ensuring a stable and secure arrangement. It’s essential to use appropriate protective padding and separators to prevent damage during transportation.

- Vertical stacking: When height is a constraint, vertical stacking can be a viable option. This technique involves stacking the panels vertically, utilizing the vertical space in a container. Proper bracing and secure fastening are critical in this configuration.

- Pyramid stacking: Pyramid stacking involves building layers of solar panels in the shape of a pyramid. This configuration maximizes the use of available space and provides stability in transportation.

By exploring these various stacking configurations and optimizing panel layout, it is possible to significantly increase the number of solar panels that can fit in a 40ft container. This not only optimizes container capacity but also ensures cost-efficiency and reduces the carbon footprint associated with transportation.

Packaging And Protection

When it comes to transporting solar panels, packaging and protection are crucial to ensure their safe arrival. Proper packaging not only prevents damage but also allows for efficient stacking and transportation. In this section, we will discuss panel packaging options for safe transportation and explore protective measures to prevent damage during shipping.

Discussing Panel Packaging Options For Safe Transportation

When packing solar panels for transportation, it is important to consider the size, weight, and fragility of the panels. Here are some packaging options for safe transportation:

- Cardboard boxes: Lightweight and cost-effective, cardboard boxes are commonly used for packaging individual solar panels. These boxes provide a buffer against external impacts and ensure the panels remain secure during transit.

- Wooden crates: For larger quantities of solar panels, wooden crates offer enhanced protection. The sturdy construction of the crates prevents any potential damage during handling and stacking.

- Pallets: Palletizing solar panels is an efficient way to transport them in bulk. By securely strapping the panels to the pallets, they can be easily loaded and unloaded using forklifts or pallet jacks.

Exploring Protective Measures To Prevent Damage During Shipping

During shipping, solar panels can be exposed to various hazards such as impacts, vibrations, and extreme temperatures. To prevent damage, the following protective measures should be considered:

- Padding: Incorporating protective padding, such as foam or bubble wrap, between individual panels can minimize the impact of vibrations during transportation.

- Corner protectors: Installing corner protectors on the edges of the panels adds an extra layer of protection and reduces the risk of corner damage.

- Secure strapping: Using strong and durable strapping materials, like nylon or steel bands, ensures that the panels are tightly secured to their packaging, minimizing movement and potential damage.

- Shock indicators: Attaching shock indicators to the packaging can provide a visual representation if the panels have experienced excessive shock or impact during shipping. This helps identify any potential damage that may have occurred.

- Temperature-controlled containers: If the solar panels are sensitive to temperature fluctuations, it is recommended to use temperature-controlled containers. These containers help maintain a stable environment, minimizing the risk of damage due to extreme heat or cold.

By implementing the appropriate packaging and protective measures, solar panels can be safely transported in a 40ft container without compromising their quality or functionality. Ensuring proper handling and adherence to safety guidelines at every stage of transportation is key to preserving the integrity of these valuable components.

Credit: cdssolar.com

Logistics And Shipping Considerations

Transporting solar panels in a 40ft container requires careful logistics and shipping considerations. Proper stacking and secure packaging of the panels is essential to maximize the number of panels that can fit in the container and ensure safe transportation.

Understanding Weight Limits And Load Capacity Of Containers

When it comes to shipping solar panels, it is crucial to understand the weight limits and load capacity of containers. Containers are designed to transport heavy goods, and exceeding the weight limits can lead to safety hazards and additional costs. It is important to calculate the weight of the solar panels along with the necessary packaging materials to ensure that it does not surpass the container’s load capacity. By adhering to these weight limits, you can ensure a smooth and secure shipping process.

Exploring Shipping Regulations And Restrictions For Solar Panels

Shipping regulations and restrictions for solar panels may vary depending on the destination country. It is essential to explore and understand these regulations to ensure compliance and avoid any delays or problems during transportation. Some countries have specific requirements for importing solar panels, such as certifications, documentation, and labeling. It is advisable to work closely with shipping and logistics experts who are familiar with these regulations to ensure a hassle-free shipping process.

Additionally, it is important to consider any restrictions imposed on the transportation of solar panels. Certain countries may have restrictions on the transportation of hazardous materials, which may include the batteries or components associated with solar panels. It is crucial to stay informed about these restrictions and make any necessary arrangements to comply with them.

In conclusion, logistics and shipping considerations play a vital role in transporting solar panels. Understanding the weight limits and load capacity of containers, as well as exploring shipping regulations and restrictions, can help ensure a smooth and successful shipping process for solar panels.

Real-life Application Examples

One of the key considerations when planning a solar panel installation is the logistics of transporting the panels to the desired location. In many cases, shipping containers are used to transport solar panels due to their durability and ease of transportation. But how many solar panels can fit in a 40ft container? Let’s explore some real-life application examples to shed light on this question.

Showcasing Successful Projects Utilizing Container Shipments

In the world of solar panel installations, container shipments have become a popular method for transporting panels to various project sites. This method ensures that the panels are protected during transit and can be easily transported to remote or challenging locations. Here are a few examples of successful projects that have utilized container shipments:

- A large-scale solar farm in Austin, Texas utilized container shipments to transport a significant number of solar panels to the site. This allowed for efficient logistics and quick deployment of the panels.

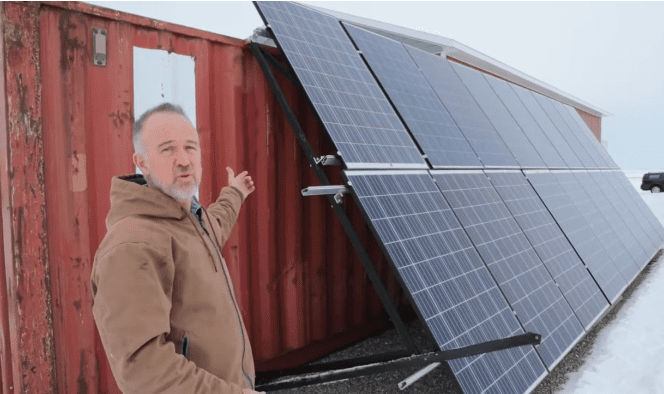

- A company in California successfully installed solar panels on top of shipping containers to power their off-grid office. This innovative approach not only provided sustainable energy but also showcased the versatility of container shipments.

- In Europe, a solar panel manufacturer used container shipments to export their products to various countries. This enabled them to efficiently distribute their panels and meet the demand in different markets.

Discussing Best Practices And Lessons Learned From Experienced Installers

Experienced solar panel installers have gained valuable insights and best practices through their hands-on experience with container shipments. Here are some key lessons they have learned:

- Securely stacking the panels: Ensuring proper stacking and securing of the panels inside the container is crucial. This not only protects the panels but also maximizes the space utilization.

- Efficient packaging: Packaging the panels in a way that minimizes the risk of damage during transportation is essential. Implementing protective measures such as padding or foam inserts can help safeguard the panels.

- Optimizing container capacity: Calculating the maximum number of panels that can fit in a container depends on various factors such as panel size, weight, and packaging. It is important to consider these factors to optimize container capacity.

- Coordinating logistics: A well-coordinated logistics plan is crucial for successful container shipments. This includes considering factors such as transportation routes, handling equipment, and customs regulations.

By following these best practices, solar panel installers can ensure a smooth transportation process and timely delivery of panels to the installation site.

Credit: www.youtube.com

Frequently Asked Questions On How Many Solar Panels In A 40ft Container

How Many Solar Panels Will Fit In 20ft Container?

Around 600 to 800 solar panels will fit in a standard 20ft container.

What Is The Capacity Of A 40 Foot Container?

A 40 foot container has a capacity for approximately 2,400 cubic feet or the equivalent of about 67 cubic meters.

How many solar panels are in a 20ft container?

The number of solar panels that can fit in a 20-foot shipping container can vary depending on the size and wattage of the panels, as well as how they are packaged. On average, you can expect to fit anywhere from 300 to 450 solar panels in a 20ft container. It’s essential to consult with the solar panel manufacturer or supplier for specific packaging and loading details, as the number of panels may vary based on factors like panel dimensions and packaging materials.

How many solar panels are in a pallet?

The number of solar panels on a pallet depends on the size and wattage of the panels, as well as the design of the pallet and packaging. Typically, you can fit between 25 to 30 solar panels on a standard pallet. However, this number may vary based on the specific dimensions and weight of the panels and the pallet used by the manufacturer or supplier.

How many solar panels are in a container?

The number of solar panels that can fit in a shipping container, whether it’s a 20ft or 40ft container, varies widely based on factors like panel size, wattage, and packaging. In a 40ft container, you can typically fit more panels than in a 20ft container. On average, you can expect to load anywhere from 600 to 900 solar panels in a 40ft container. However, this is a general estimate, and the exact number may differ based on specific panel and container dimensions. Always consult with the supplier for precise loading details.

Solar panels on top of a shipping container

Mounting solar panels on top of a shipping container is a popular application, often used to create mobile or off-grid solar power solutions. The number of panels that can be mounted on the roof of a shipping container depends on various factors, including the container’s size, the available space, and the desired power output. On average, you can install around 10 to 20 solar panels on the roof of a standard 20ft shipping container and more on a 40ft container. However, the exact number will vary based on panel size, orientation, and spacing. When installing solar panels on a shipping container, it’s important to consider weight distribution and the structural integrity of the container to ensure safe and efficient operation.

How Many Solar Panels Fit On A Pallet?

A pallet can fit multiple solar panels, but the exact number depends on the size and dimensions of the panels.

Can You Put Solar Panels On A Shipping Container?

Yes, you can put solar panels on a shipping container. Upgrade your container home or office with a solar power kit for off-grid living. Easily connect essential appliances like air-conditioners, lights, and more. Enjoy the benefits of renewable energy with this convenient solution.

Conclusion

The number of solar panels that can fit in a 40ft container depends on various factors such as the size of the panels and the container layout. However, it is possible to stack and secure multiple panels in a container to maximize the use of space.

When considering solar panels for shipping containers, it is important to consult with professionals who can provide accurate calculations and ensure proper installation. By harnessing the power of solar energy, you can transform your shipping container into an eco-friendly and sustainable living or working space.